Acrylic Vs. Polycarbonate: What’s Better For Your Custom Products

Glass is heavy, fragile, and not always the right choice for a building project. For this reason, acrylic and polycarbonate have recently grown in popularity. These materials equal only half the weight of a glass of the same size. In addition, both are considered synthetic glass types and offer excellent durability and fantastic flexibility.

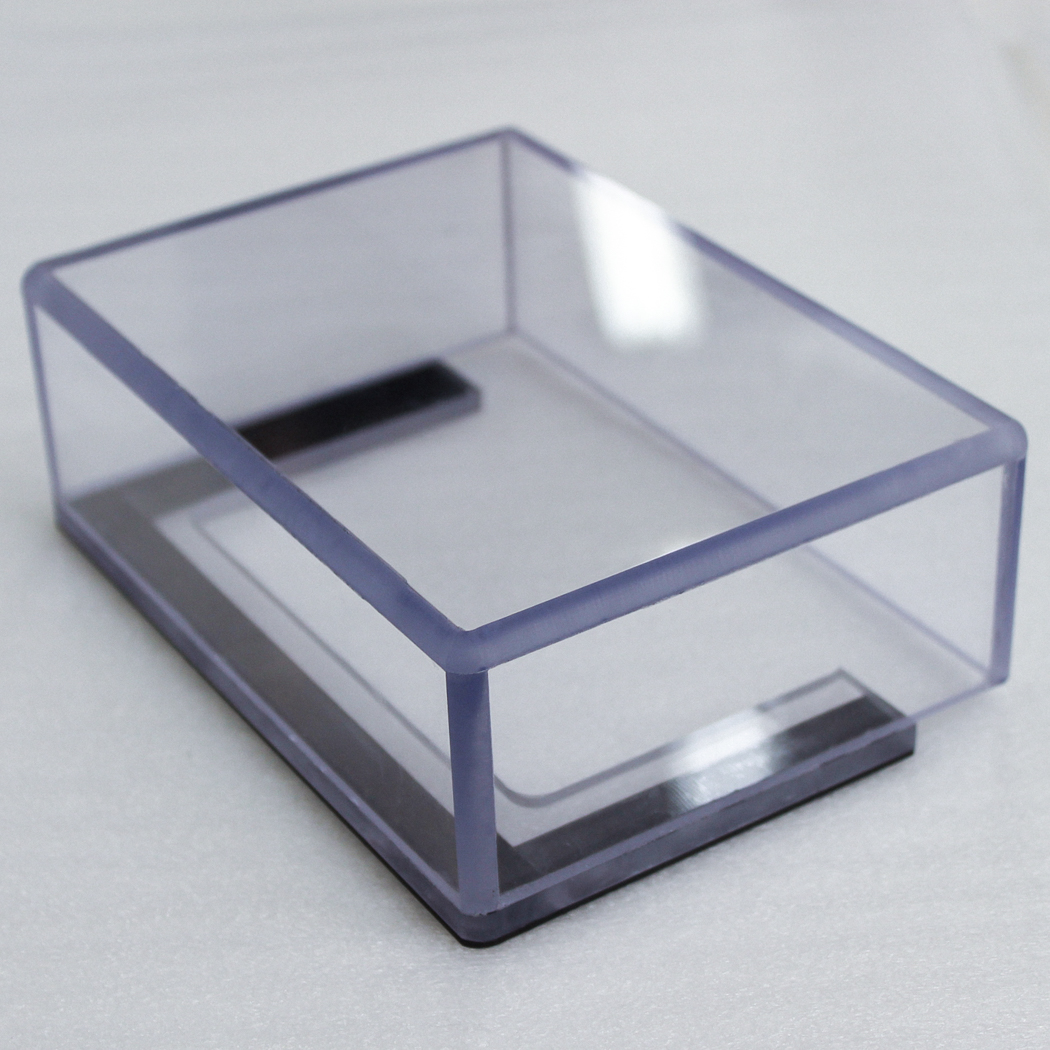

In addition to building applications, acrylic and polycarbonate are also used as cost-effective methods of protecting residential and commercial electrical devices and units.

What Are The Differences Between Acrylic And Polycarbonate?

While both of these products can be used similarly, each has its distinct advantages and disadvantages, and each can be used for different purposes.

While machine tooling is easier with acrylic than with polycarbonate, it is more likely to crack or split while being drilled. Polycarbonate is more robust than acrylic, but it also scratches more easily. When struck, acrylic can be polished to a smooth finish, but polycarbonate cannot.

What Are The Pros and Cons of Each Material?

Polycarbonate has the advantage of being more durable than acrylic but costs as much as 35% more. Plus, acrylic has excellent glue bonding, while polycarbonate is highly resistant to certain chemicals. If a shinier surface is desired, acrylic is the correct answer. But, again, polycarbonate cannot be polished.

Special precautions should be implemented when acrylic is used and is to be kept away from open flames. Polycarbonate, however, is fire-resistant and can be exposed to higher temperatures.

SmartGuard Offers High-Quality Covers For In-Demand Industries

Jobs that call for large numbers of acrylic, polycarbonate plastic, or PVC-specific plastic products often turn to SmartGuard, a Clear Industries, LLC company that offers custom acrylic, polycarbonate, and other plastic products with variations in sizes, uses, and shapes to the customer’s specifications.

We manufacture these products for any use or industry. We use these materials because of its durability and strength. The company’s goal is to introduce and develop products that greatly help plumbers, electricians, drywall workers, and painters perform their jobs more efficiently and profitably.

Reach Out To Learn More About OSHA-Approved Job Site Covers And Kits

The company’s products are manufactured in the United States and include and include a variety of workplace safety tools, covers, and kits to help you keep your job sites hazard-free.

- Residential plastic boxes

- Snap-In Clear Covers

- Temporary Breaker Box Covers

- Panelboard Covers

- Pre-Fab Device Covers

Our line of products helps protect construction sites and can help workers get through to their following projects by fabricating products that meet each person’s specific needs. This assures greater accuracy and settling for something that may or may not work.

We design and manufacture the exact products that each worker needs to do a better, more efficient job and produce only the highest quality plastic products. Contact us today to learn more about our product lineup and find the perfect covers and kits for your business.